Mist Collection – Why & How?

Metalworking industries use mist collectors on machine tools to help supply clean air, lessen the negative effects of exposure to metalworking fluids, comply with indoor air quality regulations, lower maintenance and housekeeping costs, and increase component quality. The two main elements that are generated in such metalworking industries are mist and smoke.

Mist – A hazardous substance created during metalworking processes

Mist is a liquid droplet with a diameter of 20 microns or less, formed from applications that involve the usage of lubricants and coolants, such as metal cutting, metal shaping, grinding, parts cleaning, and others. For instance, mist droplets ranging in size from 2 microns to 20 microns are routinely produced during milling and turning processes utilizing water-soluble metalworking fluids; and droplets between 0.5 and 10 microns in size are commonly produced by the same processes utilizing oil-based fluids.

Smoke – Another hazardous component in metalworking environments

Smoke is often a considerably smaller substance than mist, ranging in size from 0.07 microns to 1 micron, and it can either be a solid or liquid aerosol. Smoke is produced when a supersaturated vapour condenses or incomplete combustion occurs. Cold heading, straight oil machining of hard metals, using lube oil reservoirs on large generators, and heat treatment are examples of common applications that produce smoke.

Mist and smoke may not be visible

If you think that you can’t see mist or smoke, means that they don’t exist in your environment, you may be wrong! Any kind of metalworking processes certainly produce some or the other kind of smoke or mist, which may or may not be visible, but is certainly present. And, if ignored, the harm these elements can cause to the production environment in terms of worker exposure, upkeep and maintenance, and compliance with emissions or indoor air quality regulations can be highly dangerous! Although individual droplets smaller than 40 microns cannot be seen by the human eye, there is strong evidence that smaller mist droplets are present in most metalworking processes. This means a proper solution to this issue is eminent. One such solution is to install an oil mist collector.

What does a mist collector do?

The primary purpose of a mist collector is to take mist and smoke droplets out of the filtered airstream. Small drops of coolant must be combined into bigger ones by a collector in order to accomplish this task. The collected coolant must then be drained from the filters before they clog. There are various ways to capture such mist droplets, such as electrostatic precipitation, inertial separation, and filter media.

Electrostatic precipitation

Electrostatic precipitators work by drawing the mist-filled air through an ionizer, which gives each droplet a positive or negative charge, which are then subsequently collected by collecting cells, which push and pull the charged droplets onto the plate using alternating high voltage and grounded plates. As these droplets solidify on the plates, they are drained out of the collector. Electrostatic precipitators have a number of benefits, such as the absence of filters, relatively low energy requirements, and great efficiency when thoroughly cleaned. Electrostatic precipitators, however, demand frequent and arduous maintenance requirements. The components inside an electrostatic precipitator requires diligent cleaning to maintain the effectiveness of charging and catching the droplets.

Inertial separation

The following is how droplets carried in an airstream are separated using collectors that primarily use inertial separation. The droplets continue on their journey as the airstream is redirected around a surface, striking it as they go, eventually combining with other droplets to drain. Inertial separation comes in a variety of forms and styles, but they all have some characteristics. Inertial separators, which normally do not have main filters, can function without a barrier filtering mechanism. Yet, they typically do need fairly routine maintenance to remove any pollution from the components. Additionally, since the capture of the droplets depends on them not following the airstream, inertial separation performs better on larger droplets. Larger droplets are more likely to hit the capture surface because they have more mass, momentum, and force. For droplets with a diameter of less than 1-2 microns, inertial separators aren’t advised.

Filter media

Four filtration processes are used by collectors that use fibrous filter material to extract mist and smoke droplets from an airstream, namely, sieving, inertial impaction, interception, and diffusion.

- Sieving is the most common filtration method for bigger droplets, those larger than 10 microns. When a droplet is physically too big to travel between two or more threads, the droplet sticks to the fibre as it makes contact with it, coalesces with other droplets, and then drains from the collection.

- Inertial impaction is the filtration method that primarily collects droplets that are micron-sized and bigger. Because of the mass, the droplets are able to maintain their initial direction even after the media fibre displaces the airstream.

- Interception is the filtration process that primarily collects droplets between 0.1 and 1 microns in size. When a droplet follows an airstream but yet approaches a fibre closely enough to stick to it, interception occurs.

- Diffusion is a filtration mechanism through which very small droplets, less than 0.1 micron in size, are mostly collected. The airstream’s molecular forces, which are influenced by the droplets’ small size, cause them to flow in the same general direction as the airstream while still being independent of it.

Once the droplets stick to the fibres, they merge with other droplets on the fibres of the filter media, and when they reach a sufficient size, gravity will draw it along the fibre to the point where it will drain.

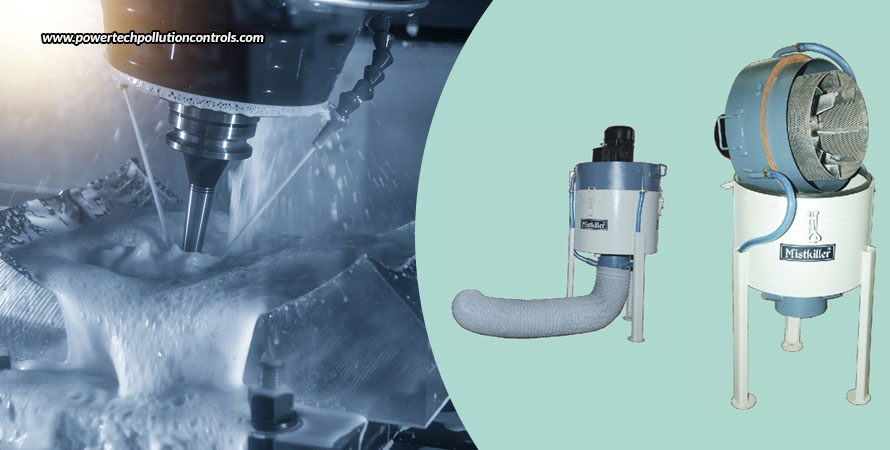

One of the best ways to capture and control the mist and smoke in your premises is by installing Powertech Pollution Controls’ oil mist collector, which is trademarked under the name of Mistkiller. This high-efficiency centrifugal mist collector is designed and developed for the control of most types of mist, generated by the use of water-based coolants or water-based liquids. This particular equipment can be easily used for applications involving CNC and non-CNC machining, cleaning chambers, and spraying systems.