The DustBag®, fitted with non-woven polyester fabric, is designed and developed in a way to be capable of capturing dust particles even as small as 10 microns.

The working principle of the DustBag®

A rectangular suction hood can be positioned close to the edge of a grinding wheel or machining tool, facing the stream of dust particles. Particles of dust are attracted into the DustBag® through the suction hood during the dust generation process. The larger dust particles in the airstream immediately sink to the bottom of the collection tank after entering the DustBag®, and the smaller dust particles are caught in the filter bag. The filter bags can be de-dusted manually or automatically, but it is not necessary to remove these bags for cleaning.

The unique features of the DustBag®

- The system has a 90% collection efficiency, capable of removing significant amounts of dust from any producing source

- Additional safety measures like pressure differential switches, fire-resistant and antistatic filter media, are incorporated for more effective results

This dust extractor can help create a workplace that is safer and healthier by removing harmful airborne pollutants. And we, at Powertech Pollution Controls, can offer top-notch factory support.

The applications

There are two ways to use the DustBag® dust collector. It can be used for machines where the grinding wheel can be partially covered by a suction hood that has been properly constructed, as well as for other applications where enclosing the wheel or milling tool is not possible. The applications include –

- Tool and cutter grinders

- Surface grinders

- Cast iron machining

- Graphite/carbon machining

- Drilling

- Milling

- Mixing

- Polishing

- Deburring

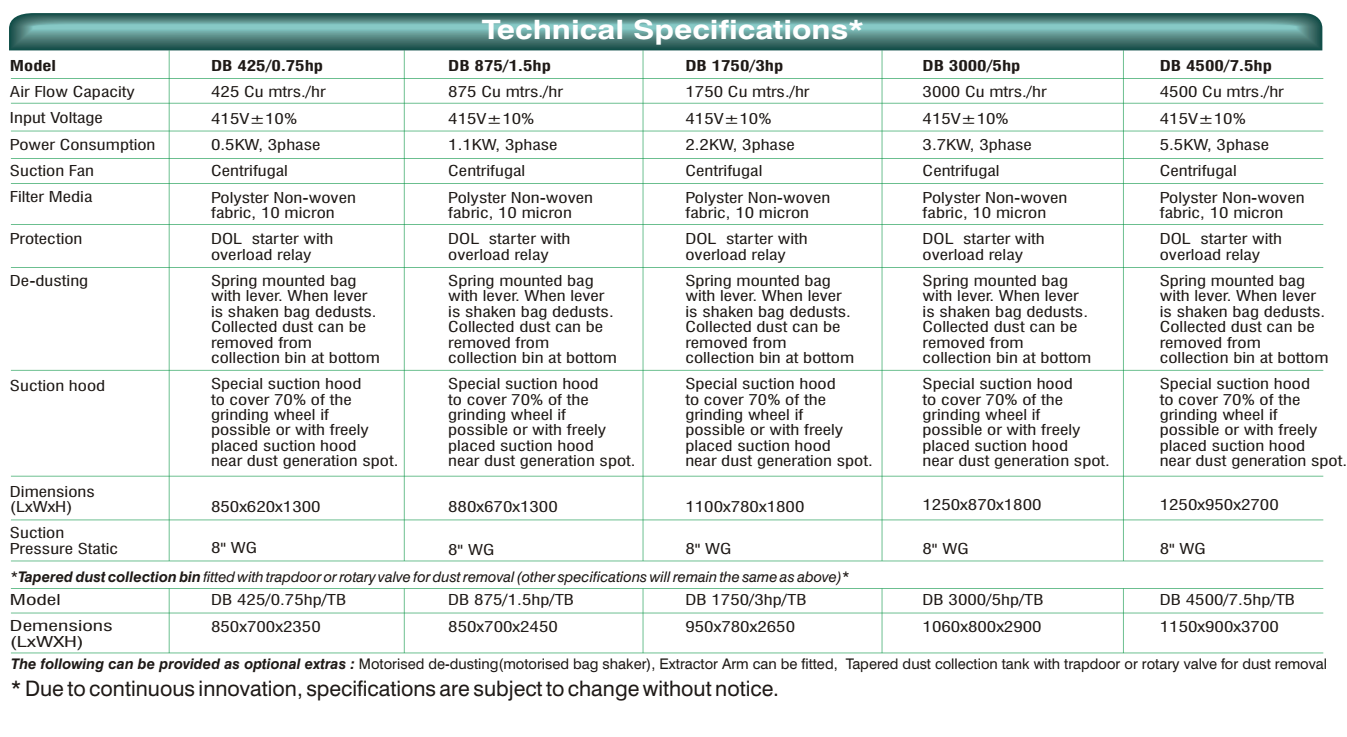

Technical Specification:

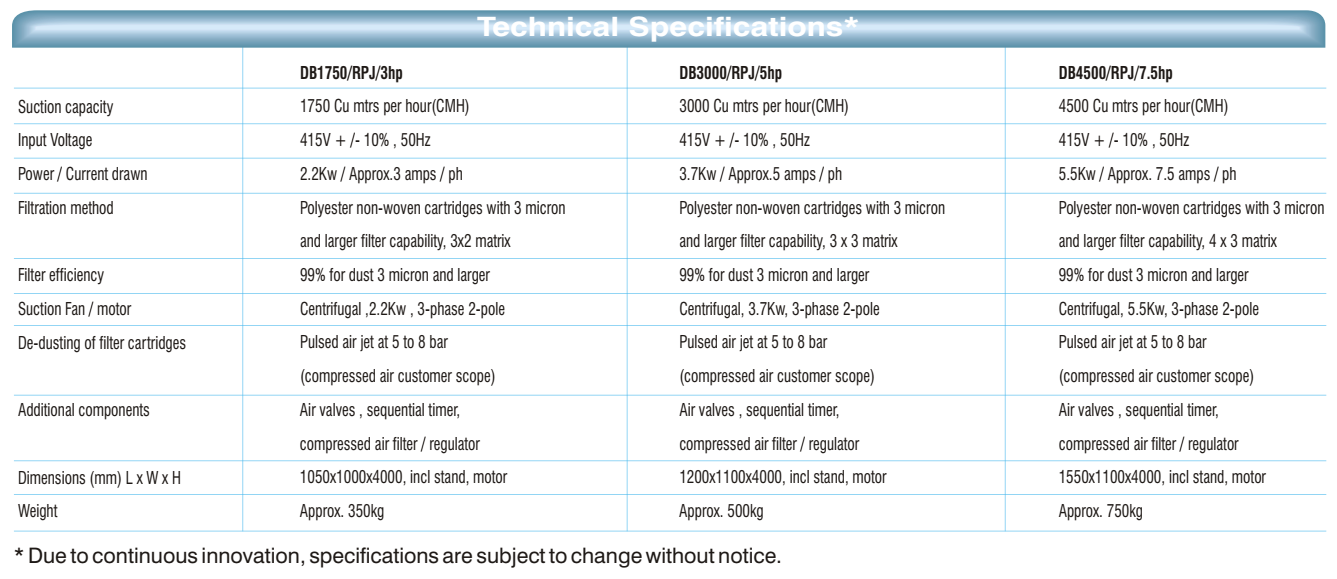

Powertech Pollution Controls Dustbag® Reverse-Pulsed-Jet (RPJ)

DustBag® Reverse-Pulsed-jet (RPJ) is a high-efficiency trademarked dust collector, designed with reverse-pulsed-jet cleaning system for the filter cartridges, manufactured for the control of majority of dust types, both fine and coarse, produced during machining operations and processes on the shop floor.

The working principle of the Dustbag® Reverse-Pulsed-Jet (RPJ)

An induction motor-driven built-in suction fan creates a strong suction that draws dust into the DustBag® Reverse-Pulsed-jet (RPJ). The suction fan outlet is equipped with a silencer to reduce noise and release the clean air. The continuous cleaning system, which de-dusts the filter cartridges, uses pulsed jets of compressed air at 5 to 8 bar (to be supplied on-site by the client), which are shot by an electronic sequential timer, into each filter cartridge. The cartridges are continuously cleaned by the pulsed air jets. The dust is taken from the rotary air lock and into the tapered collection bin after falling into it.

The unique features of the Dustbag® Reverse-Pulsed-Jet (RPJ)

- The polyester non-woven filter cartridges have a 99% effectiveness rate in filtering dust with a particle size of 3 micron and bigger.

- While in use, the Reverse-pulsed-jet constantly cleans the cartridges without pausing the DustBag process. This means that the DustBag® does not need to be shut down on a regular basis to de-dust the filter cartridges.

- With the exception of removing accumulated dust for disposal, operation is hands-free because the filter cartridges are continuously cleaned by the pulsed air-jet.

- It is possible to supply optional extras like a motorised rotary air lock, a spark arrestor with or without water cooling, a differential pressure switch, a pressure release valve and a dust collection cart.

The applications

The DustBag® Reverse-Pulsed-jet (RPJ) can be used to capture and control huge amounts of dust from the majority of dust-generating operations. The capture of dust from the machining of graphite and carbon components, ceramic dust, and talcum dust are specific applications. Additionally, it may be employed in dust-capture situations where the dust collector will operate constantly with minimal-to-no pauses.