Using cutting-edge electrostatic filtration technology, germicidal UV light, and filter media loaded with silver and titanium dioxide nanoparticles, the Dustkiller®-Bio is a dust and bio-particle controller.

The working principle of the Dustkiller® – Bio

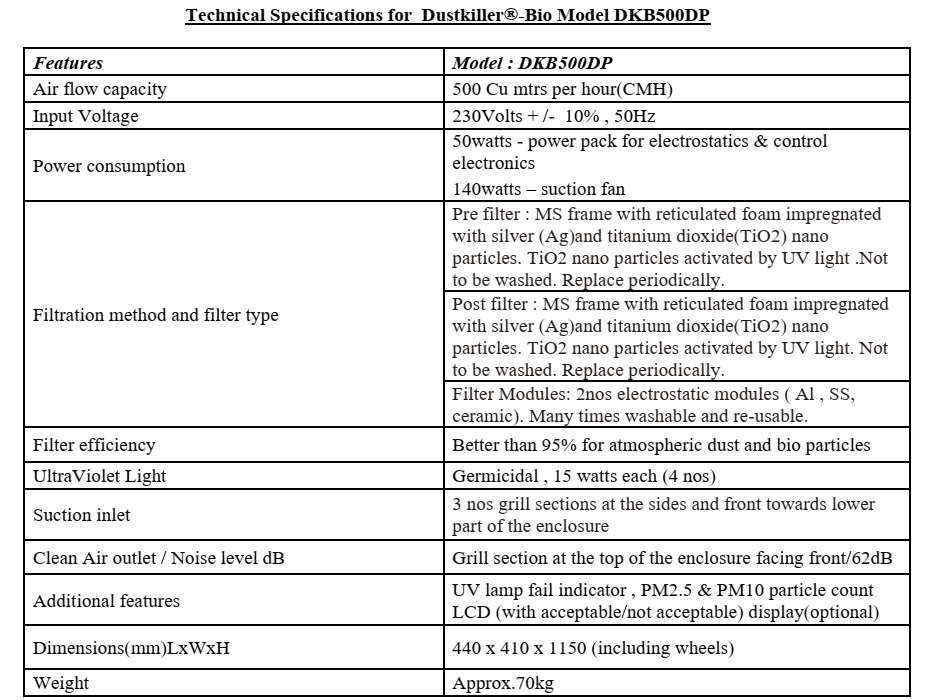

Dustkiller®-Bio suction inlets allow pollutants like dust, bacteria, fungus, and mould to enter the device through the air stream provided by an integrated, low-noise suction fan. The pollutants first reach the prefilter that is impregnated with nanoparticles, where certain dust and biological particles are trapped and made non-viable. This prefilter is also installed with a pair of germicidal lights. The remaining pollutants then enter the electrostatic modules where they are exposed to positive and negative electrostatic charges between a series of parallel aluminium plates. Similar to how iron filings are drawn to a magnet, the pollutants here are trapped on the plates. The unique aspect of this situation is that the pollutants remain stuck to the plates even after the electrostatic filter has been turned off. The leftover bioparticles are rendered non-viable by a second set of germicidal lamps and a postfilter loaded with nanoparticles. The air, now free from impurities, leaves the system through the output as pure air.

The unique features of the Dustkiller® – Bio

- The Dustkiller®-Bio can remove bacteria, fungi, and mould from any enclosed space, whether it is air-conditioned or not.

- The electrostatic filter modules are capable of removing particles as fine as 0.01 microns.

- The bio-particles can be trapped and rendered non-viable with the help of germicidal ultraviolet lights and pre/post filter media loaded with nanoscale silver and titanium dioxide particles.

The applications

In any environment where dust management and bio-particle control are necessary, the Dustkiller®-Bio can be utilized as the primary or secondary device. In settings like operating rooms, intensive care units, patient care rooms, and recovery rooms, standard sterilization and disinfection techniques like fumigation, germicidal UV sterilization, and wipe-down are utilized, which deteriorates the room over time. This is where Dustkiller®-Bio units are installed to maintain good control of pollutants in the room over time.

The maintenance

The Dustkiller®-Bio units should have trained staff to perform routine maintenance. The electrostatic filter modules must be cleaned on a regular basis using pressurized water at about 110 bar. The UV lights and sensors are wiped with a dry, spotless, lint-free cloth. The pre and post filter media cannot be washed and must be changed on a regular basis.