Fumekiller®: Cleaning Up The Air Quality While Soldering

Powertech Pollution Controls Holding the top position among Soldering Fume Extractor Manufacturers. Our brand is Fumekiller®. These machines have a suction capacity ranging from 250 CMH to 800 CMH, making them suitable for a wide range of applications. They’re like protectors because they catch all the bad smoke that comes out when you’re soldering things, such as when you do dip tinning or wave soldering. Just one machine can make the air clean in many places where soldering is done. People really like to use it to get rid of the bad smoke from places where soldering happens. It keeps everyone safe from breathing in harmful stuff.

The Working Principle Unveiled

The suction inlet is where particles from fumes, smoke, or dust enter the electrostatic filter. Smaller particles reach the electrostatic module after the larger ones are first eliminated in the prefilter. While travelling between two parallel aluminium plates, these particles acquire a high positive charge. Similar to iron filings attracted to a magnet, the particles are drawn as they move past a second set of negatively charged plates. Even when the electrostatic filter is turned off, this attraction ensures that the particles stay stuck to the plates.

Unrivalled Features of the Fumekiller®

The Fumekiller® soldering fume extractor stsands out for its great sustainability, low maintenance requirements, and built-in safety features.

Sustainability Meets Economy: Reusable filter modules result in cost savings as well as environmental consciousness.

Reduced Maintenance Costs: Compared to standard mechanical filters, experience acceptable maintenance and operational costs.

Integrated Safety Measures: Operator safety is guaranteed by high voltage fault trip circuitry, limit switches, and motor protection.

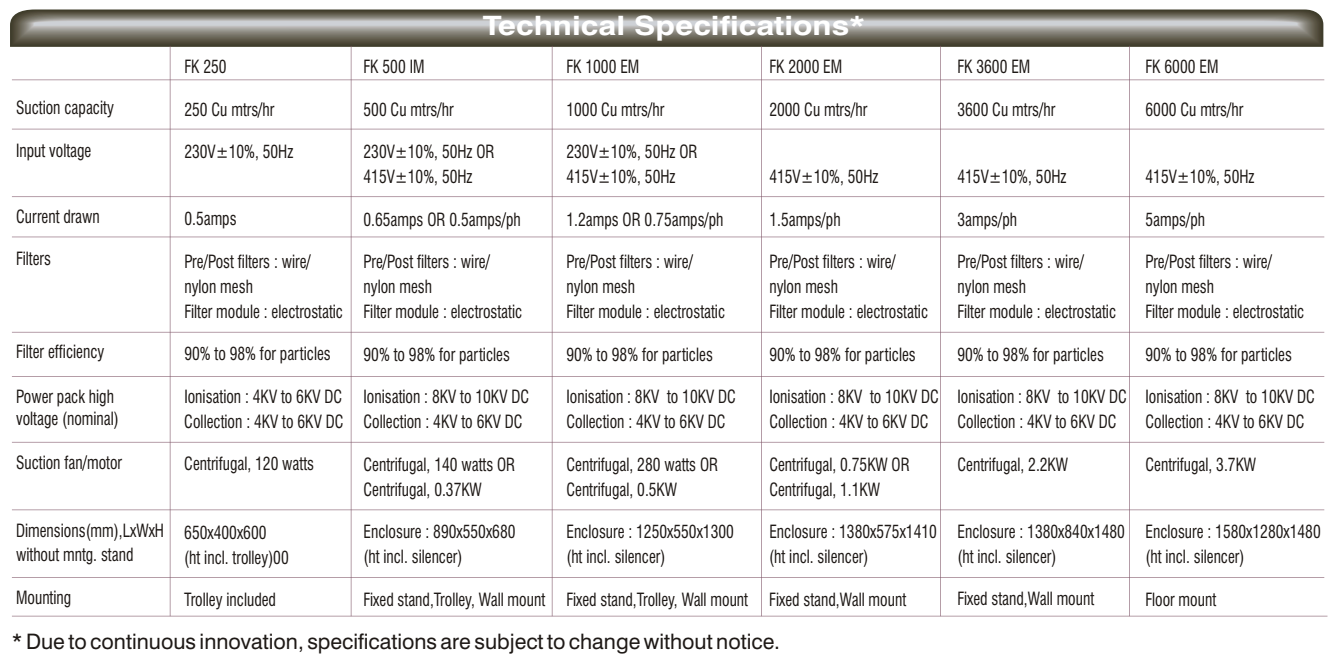

Technical Specification:

FAQs

The Fumekiller® soldering fume extractor is designed to capture fumes, smoke, and fine dust produced by welding, soldering, and similar processes, ensuring a healthier work environment. Its unique feature is the ability to be fitted with arms from a mini extractor, which can extend up to 750 mm.

Most soldering fume extractors use a combination of filters and fans to capture and remove airborne contaminants. The fan draws in the air containing fumes and passes it through filters that trap the harmful particles. Clean air is then released back into the environment. Some advanced extractors might also feature additional technologies like activated carbon filters for further purification.

Yes, soldering fume extractors come in various sizes to accommodate different workspaces and levels of usage. There are small, portable units suitable for individual workbenches and larger, more powerful units designed for industrial or heavy-duty soldering applications.

Using the Fumekiller® soldering fume extractor improves air quality, reduces harmful airborne pollutants, ensures operator safety, and offers cost-effective maintenance compared to mechanical filters.

While it’s possible to construct a simple DIY fume extractor using fans and filters, for optimal safety and effectiveness, it’s recommended to use professionally designed and tested fume extractor units build by Powertech Pollution Controls. DIY solutions might not provide the same level of filtration and containment as commercial models.