Revolutionizing Air Quality: The Fumekiller® welding fume extractor

Powertech Pollution Controls, the finest welding fume extractor manufacturers, we place a strong emphasis on promoting healthy workplaces. In the field of welding and soldering, the battle against fumes, smoke, and microscopic dust rages on. Meet our champion in this quest for cleaner air – the Fumekiller®, a welding fume extractor designed to capture and control airborne pollutants with unmatched precision.

A symphony of technology

The Fumekiller® is not just a welding fume extractor; it’s an embodiment of advanced engineering. Merging a two-stage electrostatic precipitator with electrostatic filtration technology, it serves as a sentinel to collect and control fumes, mist, smoke, and fine particles produced by welding, soldering, and related procedures.

Understanding the working principle of the Fumekiller®

Visualize the journey of particles within the Fumekiller® – a path laden with transformative encounters. Through the suction intake, these particles set out on their voyage and enter the electrostatic filter. By serving as a threshold, the prefilter filters out bigger particles. The smaller particles next enter the electrostatic module, where parallel aluminium plates surround them with a powerful positive charge. These positively charged particles are propelled by momentum to a second pair of negatively charged aluminium plates. The particles go towards these oppositely charged plates in a manner similar to how iron filings move towards a magnet, and they stick to them even when the electrostatic filter is turned off. The welding fume extractor is widely used to remove fumes generated from specific sources such as welding, soldering, wave soldering, rubber curing, oil quenching, induction hardening, wire drawing, annealing, dip tinning, die casting, and more.

Our proficiency in industrial process emission control is demonstrated by the Fumekiller®, which is more than simply a welding fume extractor. Our dedication, which is backed by years of experience, is marked by unwavering factory support and unmatched product expertise.

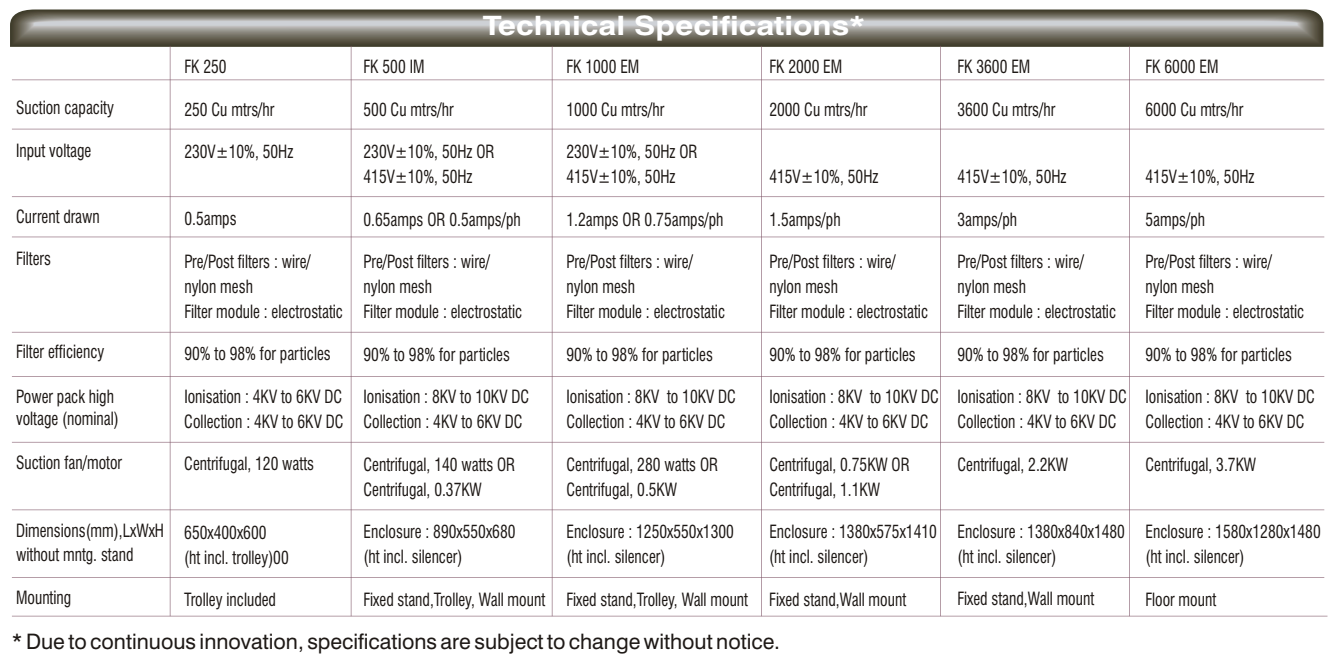

Technical Specification:

FAQs

- Over the course of the equipment’s life, the filter modules can be cleaned and reused numerous times.

- When compared to typical mechanical filters, maintenance and operating costs are less expensive.

- The equipment has integrated safety measures including motor protection, limit switches, and high voltage fault trip circuitry.

With these unique features, this welding fume extractor helps to create a workplace that is safer and healthier by removing harmful airborne pollutants. Also, based on the years of experience in industrial process emission control, we offer great factory support and product expertise.

These fume extractors offer a diverse selection of suction capacities, ranging from 1000 cubic meters per hour (CMH) to 6000 cubic meters per hour (CMH) as the standard range.

Using the Fumekiller® welding fume extractor demonstrates a commitment to employee well-being and regulatory compliance, with its advanced technology and unique features that make it a valuable addition to any welding workplace.